In conclusion, cattle panel prices are influenced by a multitude of factors, including raw material costs, seasonal demand, technological advancements, market competition, and regional dynamics. For ranchers and farmers, being aware of these variables can lead to more strategic purchasing decisions and better overall farm management. As the cattle industry continues to evolve, so too will the market for cattle panels, making it imperative for stakeholders to remain adaptive and informed in this vital segment of agriculture.

In conclusion, cattle grid fences represent a vital innovation in livestock management. They offer a functional solution for containing cattle while providing several added benefits, including land conservation, enhanced operational efficiency, and improved safety. As the agricultural industry continues to evolve to meet the demands of a growing population, tools like the cattle grid fence will be fundamental in fostering sustainable farming practices. For ranchers looking to strike a balance between productivity and animal welfare, adopting cattle grid fencing can be a step toward a more efficient and responsible approach to livestock management.

Coated chicken wire, also known as poultry netting, consists of a network of galvanized steel wire mesh that is coated with a protective layer, typically made of PVC or polyethylene. This coating not only enhances the wire's resistance to rust and corrosion but also provides a smooth finish, making it safer for both animals and humans. The mesh openings vary in size, allowing for flexibility in use depending on the intended purpose.

Wire spacers are indispensable components in the realm of electrical engineering. By providing essential separation between wires, they enhance safety, improve organization, and support the efficient operation of electrical systems. Understanding their importance and properly implementing them according to industry standards can lead to more reliable and effective electrical installations. Whether for residential, industrial, or telecommunications applications, the effective use of wire spacers ultimately contributes to a safer and more efficient electrical infrastructure.

One of the most common uses of extension springs can be found in everyday appliances. For example, they are often used in garage doors, where they help counterbalance the weight of the door, making it easier to open and close. In addition, extension springs are integral to lawnmowers, where they provide tension for the starter mechanism and ensure smooth operation.

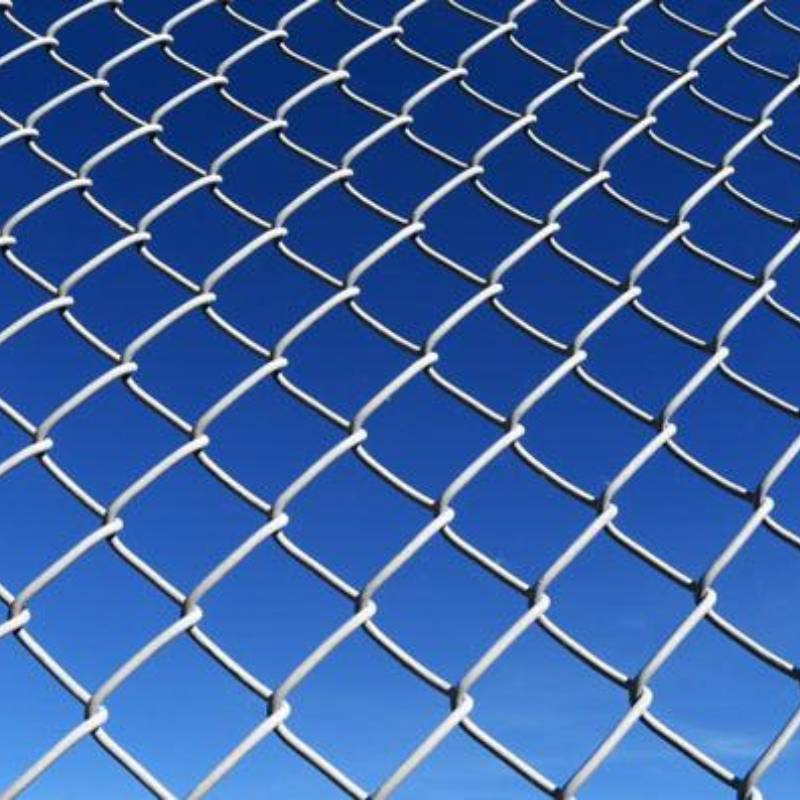

One of the foremost advantages of metal wire mesh fencing is its durability. Unlike wooden fences that can rot, warp, or be damaged by pests, metal wire fencing is resistant to many external threats. Galvanized steel, for example, is coated with a layer of zinc to prevent rust and corrosion, ensuring a longer lifespan even in harsh weather conditions. This makes metal wire mesh fencing an economical choice in the long run, as it requires less maintenance and replacement than other materials.

Flat coil torsion springs are a type of spring that exerts torque when twisted. They are made from flat strips of material, typically high-carbon steel, stainless steel, or other alloys, which are shaped into coils. The flat design enables these springs to handle loads efficiently while minimizing space, making them ideal for applications where compactness is crucial.

Plaster beads products present a captivating blend of creativity, functionality, and sustainability. Their versatile nature makes them suitable for a wide range of applications, from intricate jewelry designs to charming home décor items. Whether used for artistic expression in crafts, educational purposes, or therapeutic activities, plaster beads hold a distinct charm that continues to inspire many. As more people discover the potential of this medium, the possibilities for innovative designs and applications are limitless. Embracing plaster beads means embracing creativity, sustainability, and the joy of crafting something beautiful.

Welded wire mesh serves multiple functions across different sectors. In construction, it enhances the structural integrity of concrete slabs and walls, ensuring that they can withstand various loads. The mesh helps distribute weight evenly, reducing the risk of cracking or other failures. In agricultural settings, welded wire mesh is often utilized to create enclosures for livestock, protect crops from pests, and support climbing plants.

In conclusion, welded steel panels are revolutionizing multiple industries with their unparalleled strength, aesthetic appeal, and sustainability. Their wide-ranging applications in construction, manufacturing, and transportation demonstrate their versatility and adaptability to meet modern demands. As technology continues to advance, the popularity of welded steel panels is expected to grow, paving the way for innovative designs and structures that prioritize both performance and environmental responsibility. Investing in welded steel panels means investing in a reliable future, where strength meets sustainability in a world that increasingly values both.

The primary component of a flanged compression spring is its coil, which is made from metal wire that is coiled into a helical shape. The flanges, which are often made from the same material as the coil, reinforce the spring's structural integrity and help stabilize its position during operation. The dimensions of the flanges and the coil's diameter, wire gauge, and number of turns can be customized based on the application requirements. This versatility in design is crucial for industries that require precise spring characteristics to meet specific performance criteria.