Sealing strips are materials used to close gaps and seams around doors, windows, and other openings. They are designed to act as a barrier against air infiltration, dust, moisture, and even noise. Typically made from rubber, foam, or silicone, sealing strips come in various sizes, shapes, and thicknesses to cater to specific needs. The primary function of these strips is to create a tight seal that prevents air from escaping or entering, leading to enhanced energy efficiency.

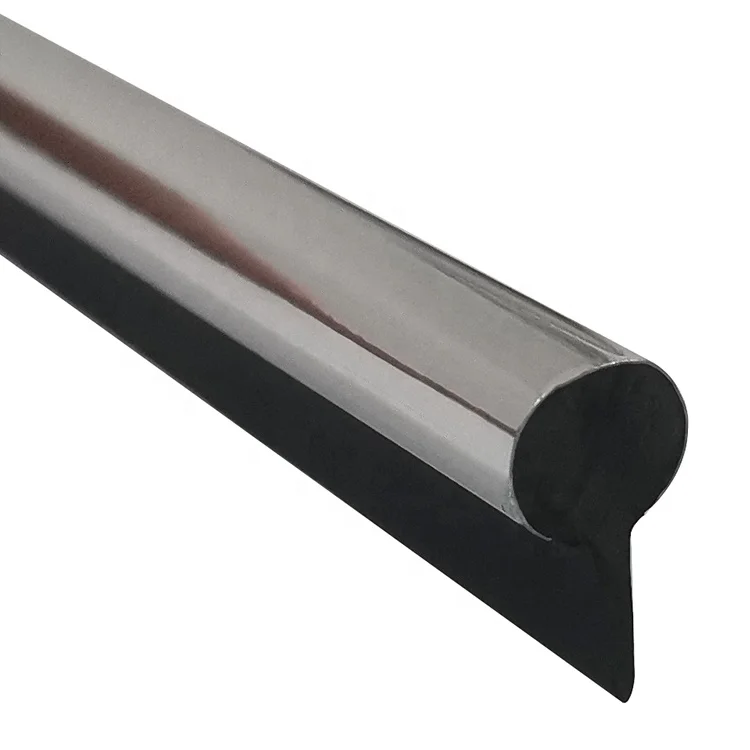

Weather door seal strips are designed to fill the gaps around doors and windows to prevent drafts, moisture, and pests from entering a building. They are typically made from durable materials such as foam, rubber, or vinyl and are available in various sizes and styles to suit different door configurations. The primary purpose of these seals is to create a tight barrier that helps maintain the inside temperature, be it warm or cool, and prevents the loss of conditioned air.

In conclusion, neon LED light strips are more than just a trendy lighting solution; they are a gateway to creativity and self-expression. Their versatility, energy efficiency, and ability to set various moods make them a popular choice for anyone looking to enhance their environment. Whether you're decorating your home, promoting your business, or diving into DIY projects, incorporating neon LED light strips can illuminate your space in the most extraordinary ways, adding a unique flair that reflects your personal style. So why wait? Light up your life with the colorful glow of neon LED light strips and transform ordinary spaces into captivating experiences.

In recent years, the appeal of neon LED lights has surged dramatically, transforming the way we think about illumination and decor. Unlike traditional incandescent and neon lighting, LED technology offers energy efficiency, durability, and versatility. As a result, the role of neon LED light suppliers has become increasingly significant in various industries, including hospitality, retail, and residential design.

From a financial perspective, the installation of foam window seal strips can lead to significant cost savings over time. The initial investment in quality foam strips is relatively low compared to the long-term savings on energy bills. Moreover, many countries, including China, are actively promoting energy efficiency measures. Government rebates and incentives can further offset installation costs, making it an economical choice for homeowners keen on improving home performance.

Made from high-quality rubber materials, these strips can withstand extreme temperatures, harsh weather conditions, and mechanical wear and tear. The manufacturing process involves mixing rubber compounds with additives to enhance properties such as tensile strength, elasticity, and resistance to UV radiation and ozone degradation. Common types of rubber used in seal strip production include EPDM (Ethylene Propylene Diene Monomer), neoprene, and silicone.

UPVC, or Unplasticized Polyvinyl Chloride, is a versatile and durable plastic commonly used in the manufacturing of windows and doors. Unlike regular PVC, UPVC does not contain plasticizers, making it more rigid and suitable for structural applications. UPVC windows and doors are appreciated for their low maintenance, high thermal insulation, and excellent resistance to weather elements, making them a preferred choice among homeowners and builders alike.

Uszczelka do bramy garażowej to element, który montuje się wzdłuż krawędzi bramy, aby zapobiec przedostawaniu się wody, zimnego powietrza, kurzu oraz insektów do wnętrza garażu. Wykonana jest zazwyczaj z materiałów odpornych na działanie warunków atmosferycznych, takich jak guma, silikon czy PVC. Uszczelki różnią się od siebie kształtem, rozmiarem oraz sposobem montażu, co sprawia, że można je dopasować do różnych typów bram – zarówno przemysłowych, jak i domowych.

Die Fabrik, die diese flachen harten Kunststoff-PP-Streifen herstellt, verfügt über modernste Technologien und Maschinen. Der Produktionsprozess beginnt in der Regel mit der Auswahl der Rohstoffe, gefolgt von der Erhitzung und Extrusion des Polypropylens. Die Extrusion ist ein entscheidender Schritt, bei dem das Material durch eine Düse gepresst wird, um die gewünschte Form der Streifen zu erhalten.