3x3 post cap

-

1%, 202%, and 13% are screw settings.

The Significance of the 1 2 13 Set Screw in Precision Engineering In the realm of precision enginee...

-

6ft round post

The Essential Guide to 6ft Round Posts Versatility and Application When it comes to construction and...

-

Creating a Durable Tensioning System for Cable Fencing Solutions

The Importance of a Cable Fence Tensioner When it comes to constructing and maintaining a sturdy fen...

-

Choosing the Right Gauge for Welded Wire Fencing to Enhance Your Property's Security and Aesthetics

The Benefits of Gauge Welded Wire Fence When it comes to securing properties or enclosing areas, the...

-

coated chicken wire for sale

Exploring the Benefits of Coated Chicken Wire for Sale When it comes to fencing, gardening, and vari...

-

6ft by 4ft fence panels

The Versatility of 6ft by 4ft Fence Panels When it comes to enhancing the aesthetics and security of...

-

Cancello nero della recinzione del collegamento della catena da 6 piedi

Un cancello in rete metallica nera da 6 piedi è un'ottima soluzione per chi desidera unire sicurezza...

-

cutting chicken wire fence

How to Cut Chicken Wire Fence A Comprehensive Guide Chicken wire is a versatile and useful material...

-

4ft x 4ft chain link gate

The Versatile 4ft x 4ft Chain Link Gate A Perfect Addition for Any Property The 4ft x 4ft chain link...

-

7 chain link fence

Exploring the Benefits of 7% Chain Link Fence When it comes to fencing options, one material that co...

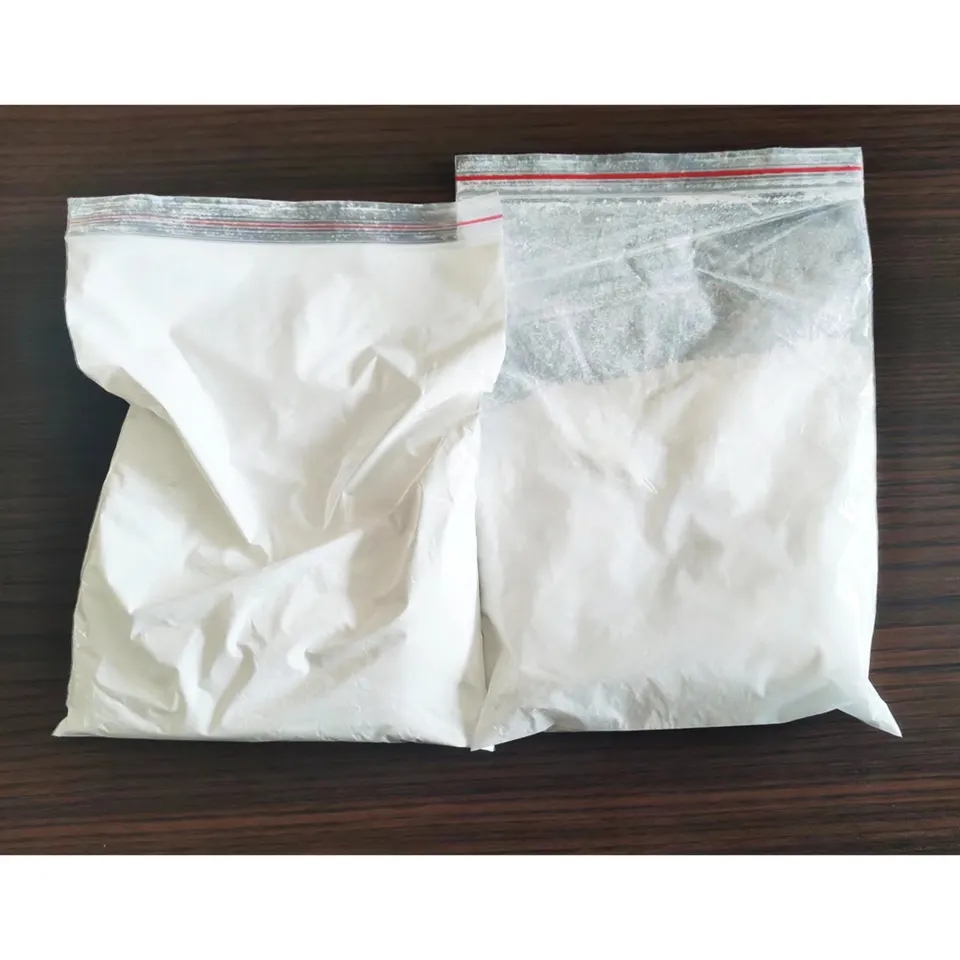

In addition, rutile is also used in the manufacturing of electronic devices, such as capacitors and transistors, due to its high electrical conductivity In addition, rutile is also used in the manufacturing of electronic devices, such as capacitors and transistors, due to its high electrical conductivity

In addition, rutile is also used in the manufacturing of electronic devices, such as capacitors and transistors, due to its high electrical conductivity In addition, rutile is also used in the manufacturing of electronic devices, such as capacitors and transistors, due to its high electrical conductivity