Metal bar grating is a type of flooring or platform made by forming a grid of parallel bars, usually made from steel, aluminum, or stainless steel. These bars are spaced apart to create an open area, allowing light, air, and water to pass through while maintaining a high load-bearing capacity. The manufacturing processes for metal bar grating include forging, welding, and pressing, with various configurations available to meet specific requirements, such as serrated surfaces for enhanced traction.

Typically, the cost of FRP grating can range from $6 to $12 per square foot, depending on the aforementioned factors. For standard applications, a budget of approximately $8 per square foot is a reasonable estimate. However, for specialized or heavy-duty applications requiring custom fabrication, costs may exceed $12 per square foot.

3. Versatility Galvanized tanks come in various shapes and sizes, making them suitable for a wide array of applications. Whether you need a small tank for gardening purposes or a large tank for agricultural operations, there is a galvanized tank that fits your requirements. They are often used for storing water, fertilizers, chemicals, and even fuel.

As environmental awareness grows, many are looking for sustainable building materials. Fiberglass is often considered a greener option compared to other materials. Although the manufacturing process of fiberglass does involve some non-renewable resources, it is durable enough to last for decades, reducing the need for replacements and minimizing waste. Moreover, several manufacturers are incorporating recycled materials into their fiberglass products, further enhancing their eco-friendliness.

Fiber Reinforced Polymer (FRP) guardrails serve as essential safety features in various transportation infrastructures, including highways, bridges, and pedestrian walkways. As technology evolves, the need for robust, lightweight, and durable materials in safety applications has become paramount. FRP materials, with their unique properties, have emerged as a front-runner in fulfilling these needs.

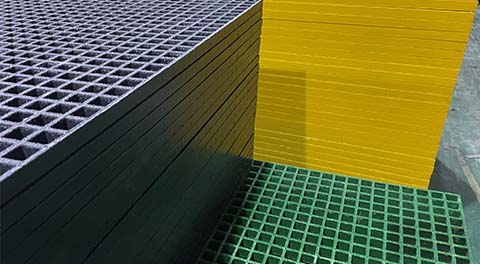

In conclusion, floor grating panels represent a versatile and practical flooring solution that caters to a wide range of applications. From enhancing safety and durability to offering environmental benefits and design flexibility, these panels meet the needs of contemporary architecture. As the industry continues to evolve, the incorporation of innovative flooring solutions like floor grating panels will undoubtedly play a key role in shaping safer, more functional, and aesthetically pleasing environments. Whether utilized in industrial settings or modern homes, floor grating panels are a testament to the ingenuity of modern design, proving that practicality can indeed harmonize with style.

In conclusion, rectangular metal water tanks represent a robust and versatile solution to the challenges of water storage. Their durability, low maintenance needs, and space-efficient design make them suitable for various applications across agricultural, urban, and industrial sectors. As water scarcity grows and environmental concerns increase, investing in efficient water storage solutions like rectangular metal water tanks will become increasingly important. These tanks not only fulfill the demand for accessible water but also support sustainability in our water management practices.

One of the primary benefits of galvanized floor grating is its exceptional durability. The galvanization process provides a barrier against rust and corrosion, which is particularly advantageous in environments exposed to moisture, chemicals, and harsh weather conditions. Additionally, the open design of the grating allows for rapid drainage of liquids and debris, helping to maintain a clean and safe working environment.

FRP is composed of two primary materials a polymer matrix and fiberglass fibers. The polymer provides the basic structural framework, while the fiberglass reinforcements enhance mechanical strength and resistance to environmental stresses. This synergy results in a material that is not only lightweight but also incredibly durable, resistant to corrosion, and capable of withstanding chemical attacks. These properties are particularly beneficial in industries where traditional materials like steel or concrete may fail due to rust, deterioration, or chemical exposure.

Water is an essential resource for life, but not all water is created equal. In many regions, especially those with hard water, the presence of excessive minerals, such as calcium and magnesium, can lead to various issues both in households and industries. Hard water can cause scale buildup in pipes, reduce the effectiveness of soaps and detergents, and even damage appliances. This is where water softener systems come into play, offering a solution to mitigate these problems.