In the realm of literature and art, the juxtaposition of various concepts often enriches our understanding of profound human emotions and experiences. One such intriguing contrast is found in the themes embodied by the Hammer and Bajo el Pozo (Under the Well). While the former symbolizes force, determination, and sometimes destruction, the latter evokes feelings of confinement, introspection, and the struggle for liberation. Together, they represent an engaging dichotomy that invites us to explore the complexities of the human condition.

Jaw plates are an indispensable component of jaw crushers, playing a major role in breaking down materials efficiently in mining and construction. Understanding their importance, types, and maintenance practices can help enhance operational efficiency and reduce costs. As industries continue to evolve, the demand for robust and durable jaw plates will undoubtedly persist, emphasizing the need for ongoing innovations in materials and engineering design. By prioritizing the maintenance and replacement of jaw plates, companies can ensure that their operations remain competitive and productive in a challenging market.

Slurry pump in the use of the process will find blockage, so how should we deal with this problem, many customers think that this is a more complex problem, but if the blockage problem is not handled well, it will cause damage to the equipment, which will also affect the efficiency of use, then slurry pump blockage problem we should pay special attention to it. So how to deal with the slurry pump blockage problem? The following part explains the treatment method of slurry pump blockage.

(1) When using the drilling rig to drill, the driver should be placed in the drilling position, so that the front end is against the rock, and the distribution should be careful to let the drilling rig move forward, so that the drill bit touches the rock; When opening the hole, first quietly let the drilling rig drive, when the drill rod is in place in the rock, it is allocated to the full open position.

(2) Before starting the drilling rig, check whether the charging pressure of the accumulator is normal; Check whether the scouring water pressure and the lubricating air pressure can be; Check whether there is sufficient lubricating oil in the lubricator, and whether the oil supply is appropriate; Check the reverse tendency of the oil pump motor. (3) If the drilling rig cannot open the hole smoothly, it should first assign the rock drill to retreat, and then let the rock drill move forward to open the hole from the beginning.

(4) When replacing the drill bit, the drill bit should be gently pressed against the rock, so that the motor of the drill can be reversed to complete the sensitive unloading head.

(5) The inspection of hydraulic components can only be prevented under the condition of pole cleaning, and after the connecting tissue is removed, it must be quickly plugged with the cleaning tightly matched plug. Before the repaired rock drill is used from scratch, it is necessary to circulate the hydraulic oil into the oil circuit to wash the components of the hydraulic system.

(6) The oil level and oil supply of the lubricator should be checked regularly; The gear with reverse structure is regularly filled with high-temperature grease; Check the oil level in the lubricating oil tank regularly and remove the dirt in the oil tank

In conclusion, the fractional head hammer is a multifaceted tool that stands out for its precision, versatility, and ergonomic design. Its applications across carpentry, metalworking, crafting, and repair work highlight its importance in various fields. As technology continues to advance and the demand for efficient, multi-functional tools grows, the fractional head hammer is likely to maintain its position as an essential asset for tradespeople and DIY enthusiasts alike. With its unique blend of functionality and control, the fractional head hammer symbolizes the evolution of traditional tools into more sophisticated options that meet the needs of modern work environments. Whether you're a professional or a hobbyist, investing in a fractional head hammer can enhance your efficiency and effectiveness in your projects.

In the dynamic realm of the drilling industry, directed drilling rods have emerged as a critical component for enhancing the efficiency and precision of drilling operations. As demand for oil, gas, and minerals continues to rise globally, the market for directed drilling rods is experiencing notable growth. This article explores the trends, factors driving sales, and the future outlook for directed drilling rods.

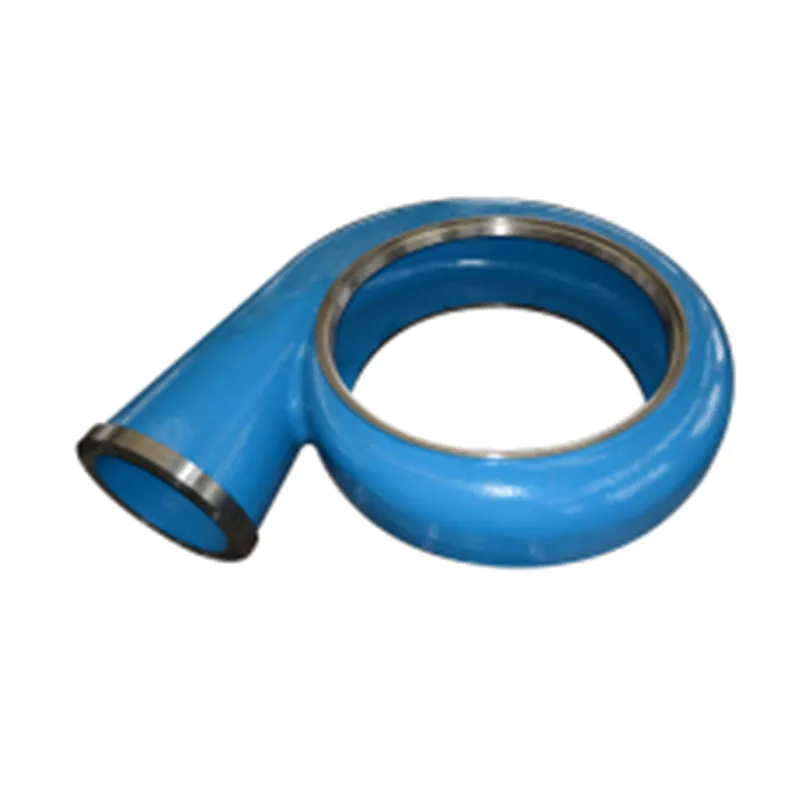

In conclusion, rubber-lined pumps are a crucial component in various industrial processes. Their robust design, versatility, and low maintenance requirements make them an attractive choice for industries that demand reliability and efficiency. As industries continue to evolve and face new challenges, the significance of rubber-lined pumps will undoubtedly grow, ensuring the safe and effective transfer of materials in an increasingly complex industrial landscape. Embracing this technology not only enhances operational efficiencies but also contributes to long-term sustainability goals in modern manufacturing and processing environments.

The roller drill uses the rolling action of the roller bit to break the rock and is suitable for drilling holes of 150 ~ 440 mm in diameter on the hard rock. It has the advantages of high efficiency and low labor intensity, and is widely used in large and medium-sized open-pit metal mines. The drill consists of an impactor (or drill bit), a rotary mechanism, a lifting mechanism, a pressure device, a walking mechanism, a slag discharge system, a drill frame and a drill pipe. Rotary drilling machines are only suitable for drilling softer minerals and coal.

Choosing the right supplier for mud pumps is a critical decision that can have significant implications for operational success in drilling and related industries. By prioritizing factors such as product quality, technological innovation, customization, and customer support, companies can forge valuable partnerships that enhance their productivity and safety. As the industry evolves, staying informed about new developments and trends will be vital for companies seeking to maintain a competitive edge. Investing time and resources into finding the right supplier will ultimately pay off in improved efficiency and reduced operational costs.

The submersible drilling rig, available in both internal combustion and electric models, is a device for drilling holes in rocks. The characteristics of drill drilling is outstanding, according to different characteristics can be divided into many varieties, different varieties of drill drilling scope is not the same, facing the classification of drill drilling, the way is briefly introduced as follows:

Submarine hammer drilling, often referred to as underwater percussion drilling, is an advanced technique utilized primarily in marine construction and resource exploration. This method combines the principles of traditional drilling with hydraulic and pneumatic operations, enabling the effective penetration of hard substrates beneath the sea floor. In this article, we will explore the processes, equipment, advantages, and applications of submarine hammer drilling.

Với nhiều lợi ích và ứng dụng phong phú, máy nén khí di động diesel không chỉ mang lại hiệu quả cao trong công việc mà còn giúp tiết kiệm thời gian và chi phí. Đối với các doanh nghiệp trong ngành xây dựng, khai thác, và sản xuất, đầu tư vào máy nén khí di động diesel là một quyết định thông minh để nâng cao năng lực và tăng trưởng bền vững. Khi chọn mua máy nén khí, hãy cân nhắc kỹ lưỡng nhu cầu và mục đích sử dụng của bạn để chọn được thiết bị phù hợp nhất.