1 4 round posts

-

Constructing a fence gate with interconnected links

Building a chain link gate is a practical and cost-effective way to enhance the security and aesthet...

-

1 2 inch welded wire fencing

The Benefits of 1% 202% Inch Welded Wire Fencing Welded wire fencing has long been a preferred choic...

-

chicken wire for floristry

The Versatility of Chicken Wire in Floristry When it comes to the art of floristry, creativity and i...

-

7ft Round Fence Posts - Durable & Stylish Boundary Solutions

Choosing 7ft Round Fence Posts for Your Outdoor Projects When it comes to enhancing your outdoor spa...

-

6 wire fence roll

The Versatility and Benefits of 6% Wire Fence Roll When it comes to fencing solutions, few materials...

-

Affordable 50 ft Chain Link Fence Cost _ Quality & Durability

When it comes to enhancing the security and aesthetics of your property, a chain link fence is often...

-

2.0 Meter High V Mesh Security Fencing for Enhanced Safety and Protection Options

The Importance of 2.0m High V Mesh Security Fencing In today's world, security is a paramount concer...

-

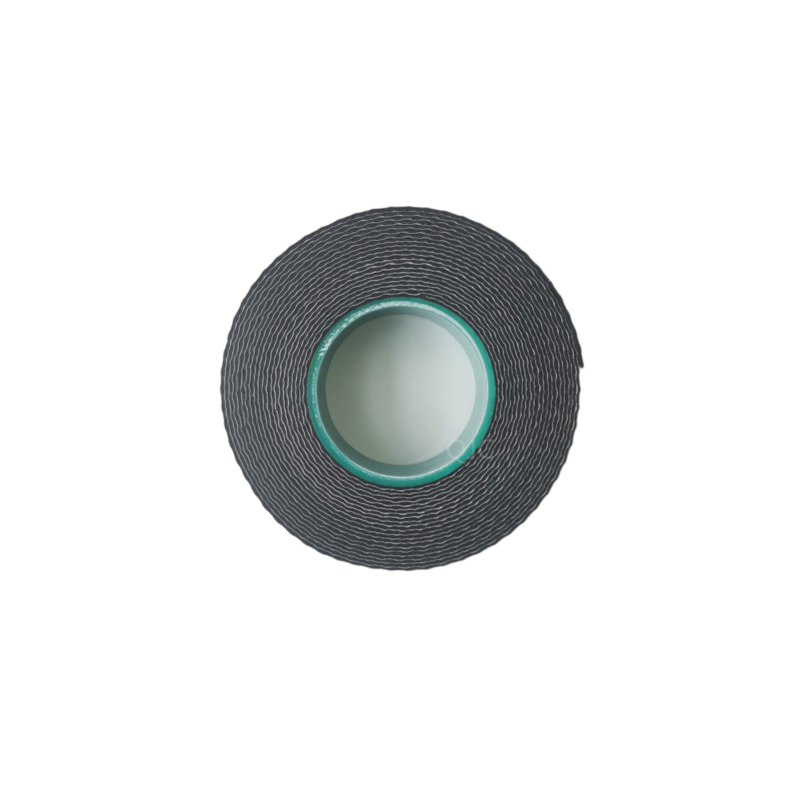

1コイルワイヤー(1 Coil Wire Meter)

1 コイルワイヤーメーターについて 近年、様々な産業で使用されるワイヤーやケーブルの需要が高まっています。その中でも、コイルワイヤーは特に重要な役割を果たしています。コイルワイヤーは、電気伝導性や機械...

-

chicken wire mesh price

Understanding Chicken Wire Mesh Pricing Chicken wire mesh, a versatile and essential product in vari...

-

8ft fence posts

Understanding 8ft Fence Posts A Comprehensive Guide When it comes to constructing a fence, one of th...

Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets

Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets Small, deliberate steps should be taken daily, reinforcing positive habits and gradually moving towards our set targets