Weather stripping is a material that seals the gaps around doors, windows, and other openings in a vehicle. For the front windshield, this elastic material is typically made from rubber or foam and is designed to create a tight seal between the glass and the frame of the car. This seal prevents water, air, noise, and dirt from entering the vehicle, which is essential for maintaining a comfortable and safe driving experience.

Waterproof foam seals are usually made from materials such as polyethylene, neoprene, and silicone. These materials are selected for their excellent water resistance, flexibility, and durability. The foam structure allows for easy compression, enabling the seals to fill gaps and create a tight fit between surfaces. This feature is crucial in preventing moisture ingress, which can lead to mold, corrosion, and deterioration of materials.

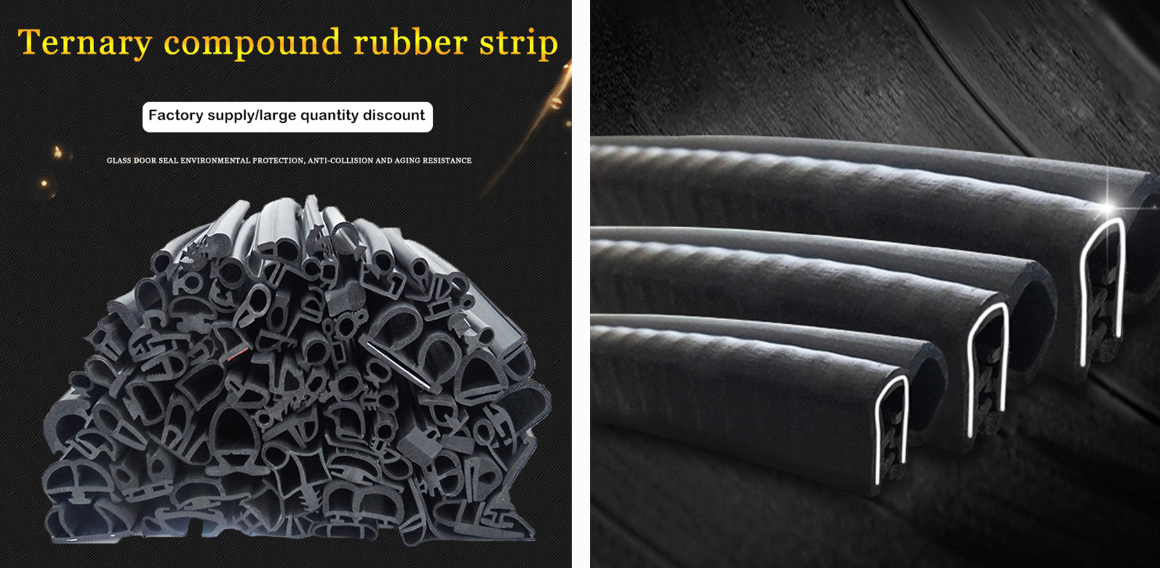

Thin rubber strips typically range from a few millimeters to several centimeters in width and can be made from various types of rubber, including natural rubber, synthetic rubber (like neoprene, EPDM, and silicone), and other elastomers. Their thin profile allows for easy manipulation, making them suitable for applications where space is limited. The flexibility of these strips enables them to bend and conform to different shapes, which is particularly useful in sealing and insulating applications.

In conclusion, silicone rubber weather strips represent a smart solution for enhancing energy efficiency, comfort, and durability in both residential and commercial applications. Their remarkable properties—such as superior insulation, resistance to extreme weather, flexibility, and sustainability—make them a preferred choice for many modern-day sealing requirements. As we continue to seek ways to reduce energy consumption and improve living conditions, the role of silicone rubber weather strips will undoubtedly become increasingly vital in our pursuit of efficiency and comfort. Embracing these innovative materials can lead to long-term benefits for the environment and the economy alike.

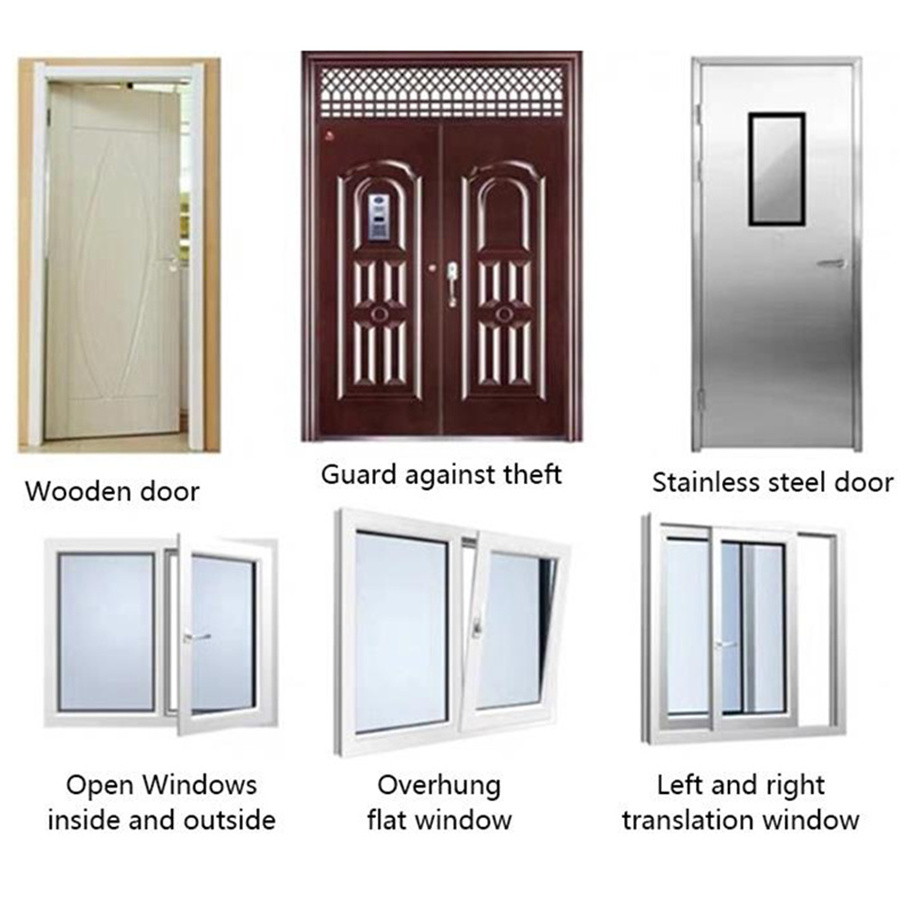

Another practical advantage of door strips is their ability to prevent pests from entering the home. Small insects, rodents, and other critters can easily squeeze through gaps beneath doors. By sealing these openings, door strips act as a barrier, keeping unwanted guests outside where they belong. This is especially important in areas with high pest populations, ensuring that homes remain a safe and healthy environment for families.

In conclusion, silicone foam strips are a versatile and highly beneficial material in various industries. Their exceptional temperature resistance, compressibility, and durability make them ideal for a wide range of applications, from sealing and insulation to consumer goods and medical devices. As industries continue to evolve and demand innovative solutions, silicone foam strips will undoubtedly play a crucial role in enhancing product performance, safety, and efficiency. Embracing the advantages of silicone foam strips can lead to better designs, improved function, and ultimately, greater satisfaction for consumers and professionals alike.

In today's world, where energy efficiency and home comfort are becoming increasingly important, self-adhesive foam door seals are a simple yet effective solution for homeowners looking to improve their living spaces. These seals are designed to fill the gaps around doors, preventing drafts and unwanted air exchanges between the indoors and outdoors. Let's explore the benefits, installation process, and various applications of self-adhesive foam door seals.

Another significant advantage of flexible rubber edge trim is its adaptability to various materials. It can be easily applied to metal, wood, plastic, and more. This versatility makes it a go-to solution for multiple industries, from automotive to construction to consumer goods. Manufacturers appreciate the ease of installation and the time saved by using these trims. They can often be cut to length, allowing for quick modifications without compromising integrity.

When choosing a glass edge rubber product, it is important to consider factors such as the size and shape of the glass edge, the level of compression required for a tight seal, and the desired aesthetic. It is also important to select a high-quality product that is resistant to UV exposure, moisture, and temperature extremes, to ensure long-lasting performance.

It serves as a perfect spacer for acrylic plates in keychains, providing a professional finish with a do-it-yourself flair It serves as a perfect spacer for acrylic plates in keychains, providing a professional finish with a do-it-yourself flair

It serves as a perfect spacer for acrylic plates in keychains, providing a professional finish with a do-it-yourself flair It serves as a perfect spacer for acrylic plates in keychains, providing a professional finish with a do-it-yourself flair