12 gauge welded wire mesh

-

6ft lap fence panels

The Benefits of 6ft Lap Fence Panels When it comes to enhancing the security, privacy, and aesthetic...

-

4 x 8 rào chắn

Tầm Quan Trọng của Hàng Rào 4% x 8% Trong thế giới xây dựng và thiết kế cảnh quan, hàng rào không ch...

-

6ft single fence panels

Understanding 6ft Single Fence Panels A Comprehensive Guide When it comes to enhancing your outdoor...

-

1_4 Inch Chicken Wire - Durable & Versatile Garden Fencing Solutions

The Versatility of 1 4 Inch Chicken Wire When discussing the essential tools for any chicken keeper...

-

5-foot tall chicken wire for effective farm fencing and chicken enclosure solutions

The Versatility of 5-Foot High Chicken Wire When it comes to fencing and enclosures, few materials c...

-

Affordable Prices for Fencing Mesh Rolls Available Now Online and In Stores

fencing mesh roll price ....

-

5 chicken wire fencing

The Versatility of 5% Chicken Wire Fencing Chicken wire fencing, often referred to as poultry nettin...

-

composite round posts

Exploring Composite Round Posts Advantages, Applications, and Sustainability In recent years, the co...

-

Designing a Short Fence with 3-Foot Posts for Enhanced Privacy and Style

The Importance of 3-Foot Fence Posts When it comes to fencing, the choice of materials and dimension...

-

Choosing the Right 5-Foot Wide Fence Panels for Your Outdoor Space

The Benefits of 5% Foot Wide Fence Panels for Your Property Fencing is an essential element for any...

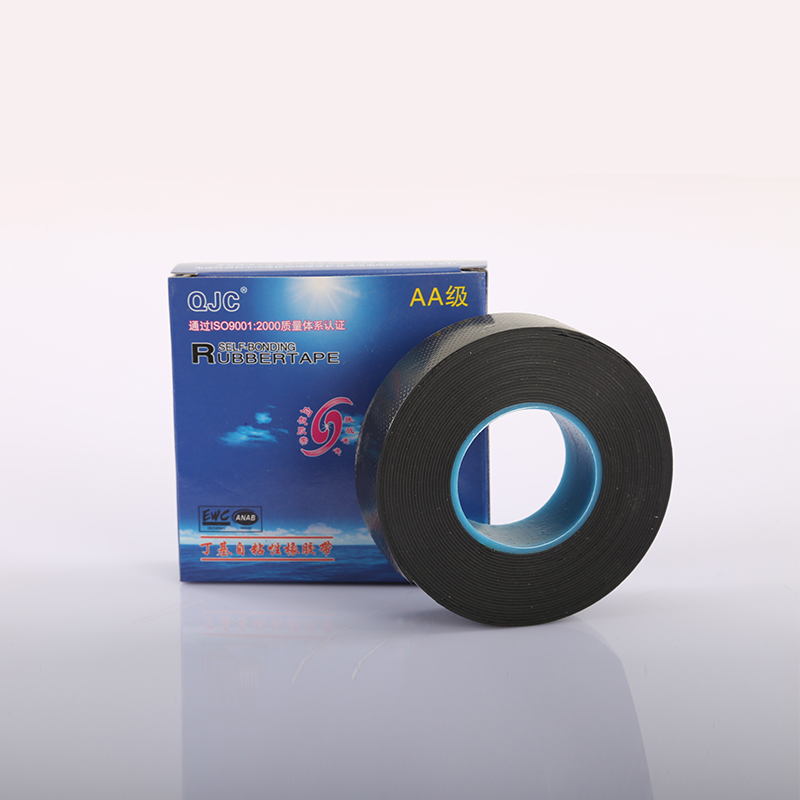

We all know that electrical tape is an important part of any electrical job. But what many people don’t know is what temperature does electrical tape melt?

In conclusion, emergency exit floor markings play a vital role in maintaining the safety and well-being of individuals in public buildings. By providing clear and visible guidance to exits, these markings serve as a critical tool in emergency preparedness and response efforts. Building owners, managers, and occupants should all work together to ensure that emergency exit floor markings are well-maintained and understood to enhance safety and security in any building. 2. **Stretching** To ensure accurate measurements, stretch the tape tightly along the floor or wall. In industrial settings, where large-scale wiring and cable management is a norm, 50mm insulation tape proves invaluable. It can effectively wrap around heavy-duty cables, ensuring they remain insulated and protected from mechanical damage. It's also commonly used in repairs, splicing, and marking of wires, further emphasizing its versatility.Polyethylene Tape’s versatility, durability, moisture resistance, and ease of use make it a valuable tool in various industries, including packaging, construction, plumbing, electrical, and sports. Its applications are extensive, ranging from surface protection to sealing, marking, and repair tasks.

The Versatile Black Flex Seal TapeWhen designing a control box, you should not take it lightly irrespective of the simplicity of the box you intend to build. Here are three factors that will help you design a functional, reliable, and safe control box.

Which control box do I need? Generally speaking, pump control boxes are selected by matching them to the horsepower, voltage, and phase of your submersible motor. Most all traditional systems are going to be single phase 230-volt applications so in most instances it comes down to matching them to the horsepower. In situations when there is overlap such as the 1hp models you can choose a QD or Standard control box. The choice usually comes down to preference. The QD box may be cheaper but the standard box will provide more room for wiring and has overload protection built in.

The materials used for floor marking range from simple paint to durable thermoplastics, vinyl tapes, and epoxy coatings. Each has its advantages; paint is cost-effective and easy to apply, while thermoplastics offer durability and high visibility. Vinyl tapes are versatile and can be used for intricate designs, and epoxy coatings provide a seamless, professional finish suitable for heavy traffic areas. Innovation is a key driver in this sector. Manufacturers are constantly researching and developing new technologies to enhance the tape's properties, such as improved heat resistance, increased tensile strength, or better UV resistance. This not only expands the tape's application scope but also ensures safer and more efficient electrical installations.Electrical control panel equipment like circuit breakers and switchgear is another common application for electrical control boxes. A breaker box needs to resist environmental conditions that might damage the sensitive electrical equipment inside.

Rubber splicing tape has come a long way since its humble beginnings. From its early roots as a simple binding material to its current status as a crucial component in modern manufacturing processes, this versatile product has proven its value time and again. As we look to the future, there is no doubt that rubber splicing tape will continue to play a vital role in a wide range of industries, driven by ongoing innovations and advancements in materials science and engineering.Statement: Some of the articles on this site come from the Internet. If there is any infringement of your interests, please contact this site.