The use of stainless steel brick ties represents a significant advancement in masonry construction. Their corrosion resistance, strength, aesthetic appeal, environmental benefits, and ease of installation make them a superior choice for modern building projects. As the construction industry continues to evolve, embracing innovative materials like stainless steel will be crucial in developing durable, sustainable, and aesthetically pleasing structures. With their numerous advantages, stainless steel brick ties are undoubtedly a smart investment for any construction project aimed at achieving long-lasting performance and reliability.

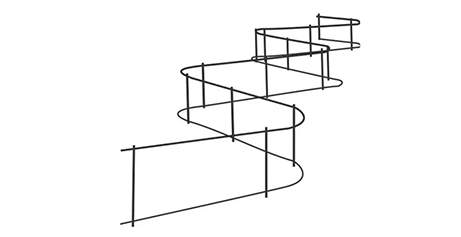

Besides providing stability, strong tomato cages can also enhance the overall gardening experience. With the plants upright, gardeners can access them more comfortably, reducing back strain during watering and harvesting. Furthermore, a well-structured garden not only looks tidier but also allows for better light exposure. Evenly spaced and vertical growth leads to improved photosynthesis, which is essential for healthy plant development and fruit production.

In addition to strength and longevity, bulk welded wire fencing offers a clean, professional appearance. The uniform grid pattern and smooth finish create an aesthetically pleasing boundary that does not obscure visibility, making it a suitable option for residential properties as well. Homeowners can use welded wire fencing to define their property lines, create safe enclosures for pets, or protect gardens from wildlife. The visibility provided by the fence allows for an open feel while still securing the area, enhancing the overall landscape design.

3. Versatile Applications Welded mesh wire can be used in a wide array of applications. In construction, it is commonly employed for reinforcing concrete, providing additional structural support. In agriculture, it serves as fencing for livestock, ensuring safety and security. Additionally, it is used in the manufacturing of cages, grates, and screens across various industries.

Welded wire mesh panels have become an essential product for various industries, from construction to agriculture. Known for their durability and versatility, these panels are made from wires that are welded at their intersections, forming a robust grid that can be customized to meet specific needs. If you are considering purchasing welded wire mesh panels, this article will provide you with insights into their features, applications, and the benefits of using them.

When it comes to securing residential or commercial properties, one of the most popular and practical options is the chain link fence. Among various heights available, a 6-foot chain link fence has gained particular attention for its balance of visibility, security, and cost-effectiveness. In this article, we will explore the features, benefits, and various applications of 6ft chain link fences.

Cattle panels can be found at various retailers, including farm supply stores, agricultural cooperatives, and online marketplaces. When shopping online, it’s essential to read product reviews, compare prices, and check for warranty options. Local farmers’ markets and livestock shows can also be excellent venues for purchasing cattle panels and gaining insights from experienced livestock owners.

In conclusion, welded wire mesh is a multifaceted material with an impressive range of applications across construction, agriculture, security, manufacturing, and DIY projects. Its strength, durability, and versatility make it an essential component in many industries, as well as in everyday life. Whether reinforcing concrete, providing security, or facilitating effective gardening practices, welded wire mesh continues to prove its value as a practical and reliable solution.

In addition to efficiency, welded wire reinforcement offers enhanced durability. The welded joints between the wires provide increased resistance to fatigue and bending, making the concrete structure more robust against dynamic loads. This resilience is particularly valuable in regions prone to seismic activity or heavy vehicle traffic, where traditional reinforcement methods may struggle to maintain structural integrity over time. Furthermore, the corrosion resistance of welded wire, especially when combined with appropriate protective coatings, enhances the longevity of reinforced concrete structures, reducing maintenance costs and extending service life.