In conclusion, high-quality rubber sealing strips are essential components that contribute significantly to the performance, durability, and safety of various applications. Their versatility, longevity, and resistance to harsh environments make them indispensable in a myriad of industries. With the ongoing advancements in materials science and manufacturing techniques, the future of sealing solutions looks promising, paving the way for even more innovative and effective sealing applications. Whether you are in automotive, aerospace, or construction, investing in high-quality rubber sealing strips is an investment in efficiency, safety, and long-term value.

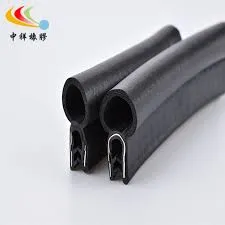

Door frame rubber seal strips are particularly effective in weatherproofing. They provide a protective barrier against rain, wind, and cold temperatures. This is especially important in regions prone to extreme weather conditions. By preventing moisture from entering through door gaps, these seals can help to protect interiors from water damage, mold growth, and other weather-related issues. Consequently, rubber seal strips enhance the longevity of door frames and associated structures.

The landscape of ABS strips manufacturing is vibrant and dynamic, driven by technological advancements and increasing demand across various sectors. As manufacturers continue to innovate and adapt to the shifting market conditions, the future of ABS strips looks promising. With a focus on quality, sustainability, and responsiveness to customer needs, ABS strip manufacturers are well-positioned to thrive in the global marketplace. The evolution of this industry not only highlights the significance of ABS materials but also underscores the broader trends in manufacturing and production in the modern economy.

Despite the positive outlook for ABS plastic exporters, the industry faces several challenges that must be navigated. Global economic fluctuations, changes in trade policies, and the increasing competition from alternative materials can pose significant hurdles. Additionally, supply chain disruptions, notably highlighted during the COVID-19 pandemic, have made logistics more complex.

In the ever-evolving world of bathroom design and functionality, maintaining a dry and clean environment is essential. One of the key innovations in this realm is the magnetic strip shower door seal. These seals serve as efficient barriers, preventing water from escaping the confines of the shower area, thus enhancing the overall experience for users. This article delves into the significance, design, and production aspects of magnetic strip shower door seals, highlighting the leading manufacturers in this niche.

Дурустии таъмир ва нигоҳдории банангоҳҳо ва ҳуҷраҳои намӣ, махсусан душ ва обанборҳо, хеле муҳим аст. Вақте ки мо дар бораи оби шикоф сухан меронем, маҳсулоте бо номи Шоҳоби оби шикоф ёдоварӣ мешавад, ки барои пешгирии ҳама гуна намии ғайрисолим ва равонашавии об истифода мешавад. Ин маҳсулот дар шохаҳои мухталифе мисли сохтмон, таъмир, ва хидматрасонӣ хеле маъмул аст.

2. Construction and Architecture In construction, flexible rubber seal strips are essential for ensuring building longevity and energy efficiency. They are employed around windows, doors, and roofing systems to prevent air and water infiltration. By enhancing thermal insulation, these seals contribute to reduced energy costs and improved indoor environmental quality, making them a favorite among architects and builders.

Window seal strips, often made of rubber or foam, are designed to fill the gaps between the window frame and the wall. Their primary purpose is to create a weather-tight seal that keeps out drafts, moisture, and dust. High-quality black window seal strips serve this purpose effectively, ensuring that buildings are energy-efficient and comfortable.

The most commonly used grades of stainless steel for channel letters are 304 and 316. Grade 304 is often chosen for its excellent corrosion resistance and good formability, making it suitable for a wide range of applications. In contrast, grade 316, which contains molybdenum, offers enhanced resistance to pitting in chloride environments, making it ideal for coastal areas or regions with high salt exposure.