100mm round steel post

-

7 foot chain link fence gate

Choosing the Right 7-Foot Chain Link Fence Gate for Your Property When securing your property or enh...

-

building your own tomato cages

Building Your Own Tomato Cages A Comprehensive Guide Tomatoes are a favorite among gardeners due to...

-

agricultural fence installers

The Importance of Agricultural Fence Installers for Modern Farming Practices In the realm of modern...

-

1 4 round posts

Exploring the Impact of 1% and 4% Round Posts on Modern Design In the realm of architecture and desi...

-

Creative Ideas for Using Grass Fence Rolls in Your Outdoor Spaces

The Versatility of Grass Fence Rolls A Sustainable Solution for Outdoor Spaces In the pursuit of enh...

-

5 foot fence panels

The Benefits of 5% Foot Fence Panels A Comprehensive Guide When it comes to enhancing your property'...

-

6 feet by 50 feet chicken wire available.

Understanding and Utilizing 6 ft x 50 ft Chicken Wire A Comprehensive Guide Chicken wire, a versati...

-

decorative garden fences

The Charm of Decorative Garden Fences Decorative garden fences are not just functional barriers; the...

-

3 post cap

Understanding the 3% Post Cap Implications and Application in Financial Markets The concept of a 3%...

-

2x2 metal post caps

The Versatility of 2x2 Metal Post Caps Enhancing Aesthetics and Durability When it comes to home imp...

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials

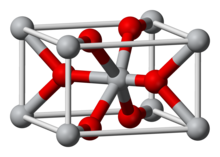

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials This intermediate compound is then refined further and reacted with oxygen at high temperatures to yield titanium dioxide This intermediate compound is then refined further and reacted with oxygen at high temperatures to yield titanium dioxide

This intermediate compound is then refined further and reacted with oxygen at high temperatures to yield titanium dioxide This intermediate compound is then refined further and reacted with oxygen at high temperatures to yield titanium dioxide