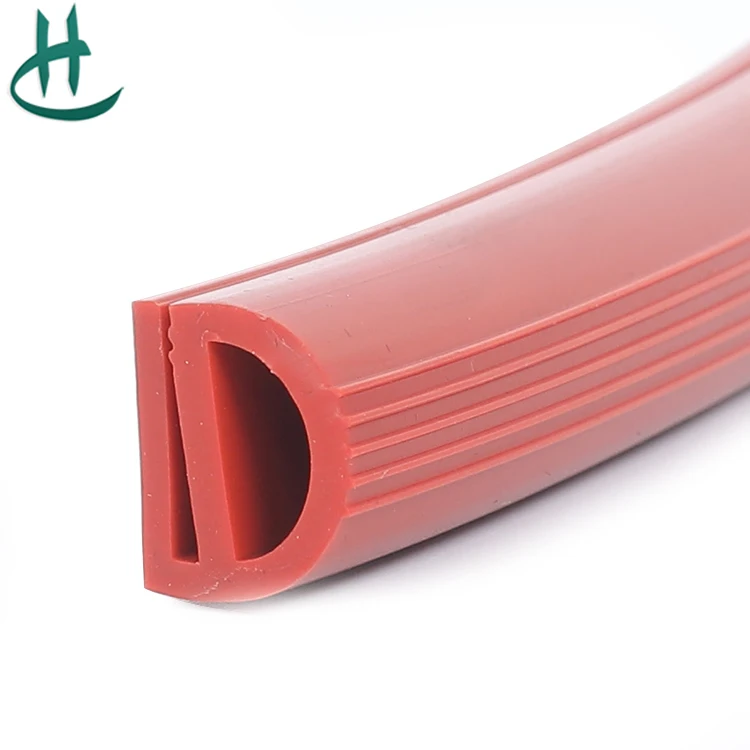

Rubber seal strips are flexible components made from various types of rubber materials, including EPDM, silicone, and neoprene. They are primarily designed to provide sealing solutions that prevent the ingress of moisture, dust, air, and other environmental elements. Their typical applications include automotive door seals, window trims, HVAC systems, and a myriad of other mechanical systems that require reliable sealing capabilities.

LED split neon is a modern alternative to traditional neon lights. Unlike conventional neon tubes, which utilize gas-filled glass tubes to produce light, LED split neon employs flexible LED strips encased in a soft, flexible material. This construction allows for intricate designs, curves, and shapes that were previously challenging to achieve with standard neon lighting. The design flexibility, coupled with low energy consumption and high efficiency, makes LED split neon an attractive option for both commercial and residential applications.

2. Weatherstripping There are various types of weatherstripping, including V-strip, felt, and tubular rubber or vinyl. V-strip is particularly effective for sealing the edges of doors, while tubular rubber or vinyl provides excellent durability and insulation against cold drafts. Felt weatherstripping can serve as a budget-friendly option, but it typically offers less insulation over time.

In conclusion, LED neon strip light factories play a crucial role in the evolving landscape of modern lighting solutions. Their ability to produce high-quality, energy-efficient, and customizable products positions them at the forefront of the lighting industry. As consumer preferences lean toward innovative and sustainable options, these factories are poised for continued growth and success. The future of illumination is bright, colorful, and undeniably luminous thanks to LED neon strip lights.

When considering light box silicone strips, understanding the pricing structure is essential for making informed purchasing decisions. By assessing the factors that influence costs, such as material quality, customization options, and supplier reputation, businesses can find the right balance between budget and quality. Ultimately, investing in high-quality silicone strips not only enhances the visual appeal of advertising displays but also contributes to more effective communication of brand messages. As businesses continue to seek innovative ways to stand out, light box silicone strips will remain a valuable asset in achieving those goals.

Sealing strips play a crucial role in various industries, serving as essential components for ensuring the integrity and efficiency of products. From automotive to construction, sealing strips are utilized in diverse applications, contributing significantly to enhanced performance, energy efficiency, and overall safety. This article will delve into the various types of sealing strips, their applications, and their importance in modern manufacturing processes.

Waterproof sealing strips are designed to prevent water ingress, ensuring that devices and structures remain protected from moisture and environmental elements. They are typically made from a variety of materials, including rubber, silicone, and polyurethane, which offer exceptional flexibility and resilience. The selection of material is crucial and often depends on the specific application and environmental conditions to which the sealing strip will be exposed.

In conclusion, custom car rubber sound seal strips are an essential feature that enhances vehicle comfort and performance. From significant noise reduction and protection against the elements to improved energy efficiency and a tailored aesthetic, the benefits are clear. For car enthusiasts and everyday drivers alike, investing in high-quality, custom sound seal strips can lead to a more enjoyable driving experience. As the automotive industry continues to innovate, it is crucial to consider every aspect of vehicle performance, and sound seal strips are a vital part of that equation. Whether you're commuting to work or hitting the open road for an adventure, the right sound seal strips can make all the difference.

Manufacturing these strips involves several processes, including extrusion, cutting, and finishing. Extrusion is the primary method used, wherein heated aluminium is forced through a die to create long sections of the desired profile. This technique allows for precision and consistency, ensuring that each seal strip meets the exact specifications required by manufacturers and builders.

In recent years, the demand for LED neon lights has surged dramatically, driven by advancements in technology, a push for energy efficiency, and a growing interest in personalized aesthetics. LED neon light boards, with their vibrant colors, versatility, and low energy consumption, have become a popular choice for businesses and individuals alike. As a result, a new wave of exporters is emerging in this sector, bringing these innovative lighting solutions to markets around the world.

3M seal strips are designed to provide optimal sealing in varying environments. These strips are available in a multitude of materials, including foam, rubber, and silicone, each serving unique purposes. Foam seal strips, for example, are ideal for creating airtight seals around windows and doors, minimizing energy loss. Rubber seal strips are particularly effective in high-wear areas, while silicone strips offer flexibility and durability, making them suitable for a wider range of applications.