Water quality is of utmost importance, and stainless steel provides an excellent solution for maintaining hygiene. Unlike tanks made from plastic or rubber, stainless steel does not leach harmful chemicals or contaminants into the water. It also has a smooth, non-porous surface, making it less susceptible to bacterial growth, in turn ensuring that the stored water remains clean and safe for consumption. For applications in the food and beverage industry, adhering to stringent hygiene standards is critical, and stainless steel tanks are often the preferred choice.

In commercial settings, square wire mesh fences can serve as security enclosures for warehouses, factories, and storage yards. The strength of the wire ensures that intruders are deterred, while the visibility of the fencing allows for light and air circulation, preventing a claustrophobic environment. With options for heights, thickness, and coatings, these fences can be tailored to meet specific security threats.

In conclusion, the 2x4 welded wire mesh is a versatile and durable material that offers a wide range of applications in various industries. Its strength, flexibility, and corrosion resistance make it an ideal choice for projects where structural integrity and longevity are essential. Whether used in construction, agriculture, landscaping, or any other industry, the 2x4 welded wire mesh is sure to deliver consistent performance and reliable results.

In terms of installation, nails typically have a quicker application process than screws. Using a hammer, a skilled carpenter can drive nails into the material rapidly, making it an efficient choice for large projects, such as roofing or framing. Additionally, nails are less susceptible to bending during installation, which can be a concern with screws if they encounter resistance when being driven in.

Double twisted black annealed iron wire is produced by twisting two strands of iron wire together, with a specific annealing process that enhances its malleability and reduces brittleness. The annealing process also gives the wire a distinct black appearance due to the oxidation that occurs, which can provide additional corrosion resistance in certain environments. This wire is primarily used in construction, agriculture, and fencing, making it an essential product across various sectors.

In summary, a welded razor mesh factory plays a crucial role in producing one of the most effective security solutions available today. Through a meticulous manufacturing process, high-quality materials, and a commitment to excellence, these factories deliver products that meet the rigorous demands of various industries. As security concerns continue to rise, welded razor mesh remains an essential component in safeguarding properties and enhancing overall security measures. By investing in this advanced technology, businesses and homeowners alike can rest assured knowing that they are protected by one of the toughest barriers on the market.

Galvanization is a process that involves coating iron or steel with a layer of zinc to prevent corrosion. In a marine setting, where constant exposure to water, salt, and varying weather conditions is a given, using galvanized materials can significantly increase the durability and longevity of structures. Galvanized boat nails are specifically designed to withstand these conditions without succumbing to rust and deterioration, making them an ideal choice for boat construction and repairs.

Market demand is another pivotal element affecting pricing. For instance, during construction booms, the demand for wires and other building materials tends to surge, which can drive prices up. Similarly, seasonal agricultural needs can lead to spikes in demand for specific wire types used for fencing or trellising crops. Therefore, staying abreast of market trends and customer requirements is vital for stakeholders involved in the wire industry.

The demand for U-type nails is substantial in various sectors, including construction, DIY home improvement, and manufacturing. As the construction industry grows globally, so does the need for reliable fasteners like U-type nails. Additionally, the DIY trend, spurred by social media and home improvement shows, has led to increased consumer interest in these products, further expanding market prospects.

SS wire mesh, short for stainless steel wire mesh, is a versatile and durable material used in a variety of applications. Made from stainless steel wire, this type of mesh offers high tensile strength, corrosion resistance, and temperature resistance, making it ideal for use in a wide range of industries.

While fiberglass septic tanks offer benefits such as lightweight installation and resistance to certain elements, it is crucial for homeowners to carefully weigh these advantages against the potential disadvantages. Issues related to durability, cost, environmental vulnerability, insulation properties, chemical sensitivity, and maintenance challenges should all be considered before making a decision. By fully understanding the drawbacks, homeowners can ensure they choose the most suitable septic tank material for their needs, ultimately contributing to the efficiency and longevity of their septic systems.

Wire mesh and netting are essential materials that find applications across various industries due to their versatility, strength, and durability. These materials consist of interconnected strands of wire, which can vary in size, shape, and material, making them suitable for numerous uses. From construction and agriculture to security and decorative applications, wire mesh and netting are integral components in many facets of modern life.

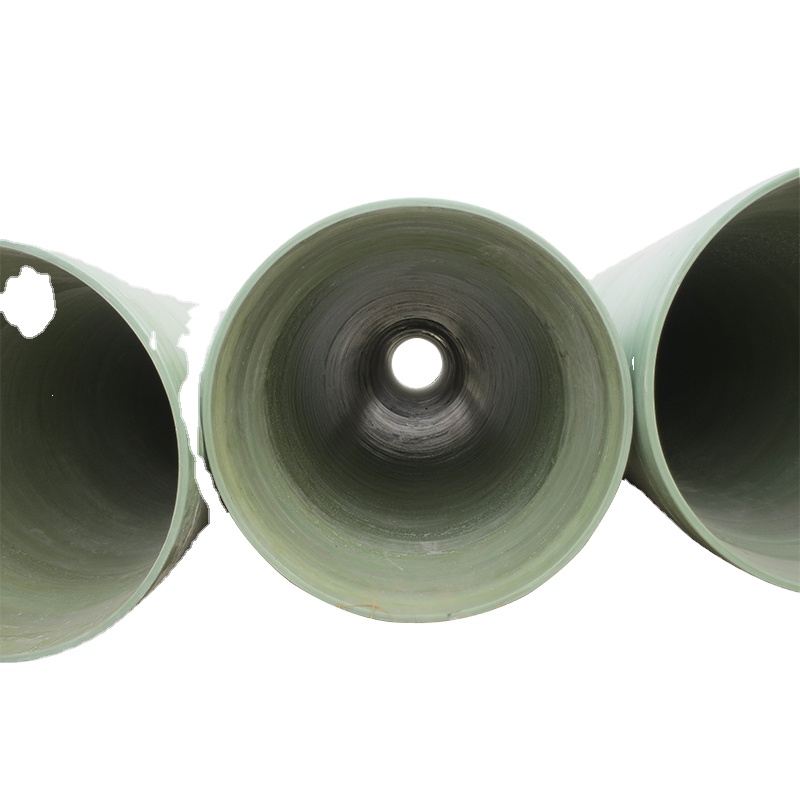

The development of pipe machines traces back to the industrial revolution when mass production became essential. Early pipe-making methods were labor-intensive, relying heavily on manual labor and rudimentary tools. However, as technology advanced, the need for efficiency and precision in pipe production led to the invention of machine tools specifically designed for this purpose. Over the decades, advancements in engineering and manufacturing techniques have transformed pipe machines into highly sophisticated equipment capable of producing pipes of various materials, including steel, plastic, and composite materials.

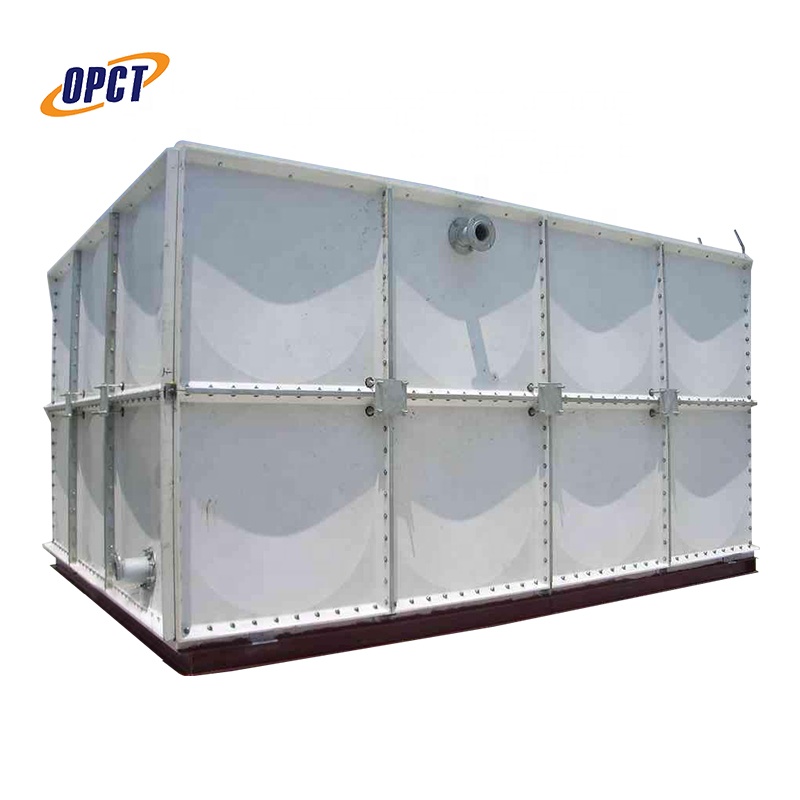

These tanks can be customized to meet the specific needs of a business, with options for different sizes, shapes, and configurations These tanks can be customized to meet the specific needs of a business, with options for different sizes, shapes, and configurations

These tanks can be customized to meet the specific needs of a business, with options for different sizes, shapes, and configurations These tanks can be customized to meet the specific needs of a business, with options for different sizes, shapes, and configurations The coating provides a clean, silver finish that complements most building materials The coating provides a clean, silver finish that complements most building materials

The coating provides a clean, silver finish that complements most building materials The coating provides a clean, silver finish that complements most building materials