Understanding HPMC viscosity is crucial for optimizing its use in various applications. The intricate relationship between viscosity, formulation ingredients, and environmental conditions demands careful consideration during product development. As industries continue to innovate and seek improved solutions, the role of HPMC—and its viscosity—will undoubtedly remain significant. By comprehensively understanding and manipulating HPMC viscosity, manufacturers can enhance product performance, meet consumer needs, and drive industry advancements.

Sa kabuuan, ang HPMC cellulose ay isang napakahalagang sangkap na may malawak na aplikasyon sa iba't ibang industriya. Mula sa konstruksyon, pagkain, hanggang sa medisina at personal na pangangalaga, ang HPMC ay nagbibigay ng mga benepisyo na hindi matatawaran, kaya't nananatili itong isang pangunahing bahagi ng maraming produktong ating ginagamit sa araw-araw.

CMC, known for its ability to enhance the stability of drug suspensions, is often incorporated into oral and topical formulations. Its thickening properties help achieve the desired consistency, ensuring that medications remain evenly distributed and effective. Moreover, both HPMC and CMC are used as excipients in tablet formulations, aiding in the binding process and improving the overall integrity of the tablets.

HPMC is a cellulose derivative that is commonly used in pharmaceutical, food, and cosmetic industries. It is a non-ionic polymer that exhibits excellent film-forming, thickening, and binding properties. When incorporated into detergents, HPMC enhances the cleaning efficiency and overall performance of the product. The molecules of HPMC have a capacity to interact with water, which allows it to dissolve easily and create a stable solution when mixed with other ingredients.

In conclusion, hydroxyethyl cellulose is a multifaceted compound with applications spanning several industries. Its roles as a thickener, stabilizer, and texture enhancer make it invaluable in pharmaceuticals, cosmetics, food products, construction materials, and adhesives. As research and development continue to expand, the potential uses of HEC are likely to grow, promising innovative solutions and sustainable alternatives in various fields.

In today's digital landscape, where remote work and virtual collaboration are becoming increasingly prevalent, the Remote Desktop Protocol (RDP) has emerged as an essential tool. RDP, developed by Microsoft, allows users to connect to another computer over a network connection, enabling them to access applications and files as if they were physically present at that machine. This capability is especially valuable in an era where flexibility and mobility in the workplace are paramount.

1. Construction Industry RDPs play a vital role in enhancing the performance of cement-based materials. They are commonly used in tile adhesives, flooring compounds, and joint fillers. By incorporating RDPs, manufacturers can improve the flexibility, adhesion, and water resistance of these products. This leads to longer-lasting materials that can withstand changing environmental conditions.

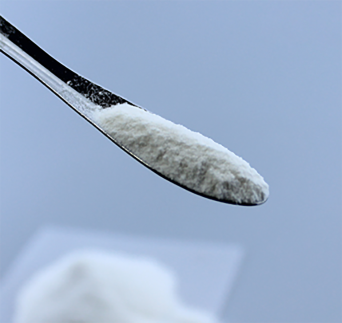

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used polymer in various industries, ranging from pharmaceuticals to construction. Due to its unique properties, HPMC has become an essential ingredient in various applications, including as a binder, thickening agent, and emulsifier. With the growing demand for HPMC, it is crucial for businesses and individuals to understand what to consider when purchasing this compound.

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose derivative widely used in various industries due to its unique properties. HPMC is synthesized by the chemical modification of cellulose, a natural polymer sourced from plant materials. This modification imparts several beneficial characteristics to HPMC, including water solubility, thickening efficiency, and film-forming ability. The types of HPMC vary mainly based on their methoxy and hydroxypropyl content, each type serving distinct purposes across multiple applications.

Another remarkable property of HPMC is its ability to form films. When dried, HPMC solutions create a flexible, semi-permeable film, making it useful in coatings for tablets and capsules. This film-forming property is crucial in controlling the release of active pharmaceutical ingredients, allowing for sustained or delayed release formulations. Additionally, in the construction industry, HPMC is often added to mortar and concrete to improve adhesion and workability.

Истеҳсолкунандагон ва фурӯшандагон иҷозат доранд, ки ба нарх ва сифати Гидроксиэтил целлюлоза диққат диҳанд, то эҳсос кунанд, ки кифоя аст ё на. Бо назардошти ин, бояд қайд шавад, ки бо ташкил кардани муомилаҳо ва ҳамкорӣ бо таъминкунандагони боэътимод, нархи Gidroxietilsellyuloza метавонад дар чаҳорчӯби нархҳои муқаррарӣ ва стандартӣ қарор гирад.

Ҳидрофил ҳидрогел, ки бо номи Гидроксиэтил целлюлоза (HEC) маълум аст, давоми солҳои охир дар соҳаи саноат ва тиббати моддаҳои кимиёвии истифода шавад. Ин модда дар раванди истеҳсолот, хусусан дар соҳаҳои сохтмон, косметика, ва хӯрокворӣ, муҳими махсусе дорад ва бо ин ҳол, нархи он метавонад ба вокунишҳои бозор ва талабот вобаста бошад.