In the realm of construction and manufacturing, seal strip glass channels play a crucial role in ensuring the integrity and durability of glass installations. These components are essential for windows, doors, and various glass structures, providing a secure and watertight fit. As the market for these products evolves, understanding their pricing intricacies becomes increasingly important for both consumers and manufacturers.

Channel letters are illuminated or non-illuminated signs typically found on the exterior of buildings. They are made from durable materials, like metal or plastic, and can be customized in various sizes, fonts, colors, and styles. The 26mm size strikes a balance, making it easy to see from a distance, yet not overwhelmingly large, thus suitable for buildings of varying scales. The use of channel letters not only boosts brand visibility but also enhances the overall aesthetics of a location.

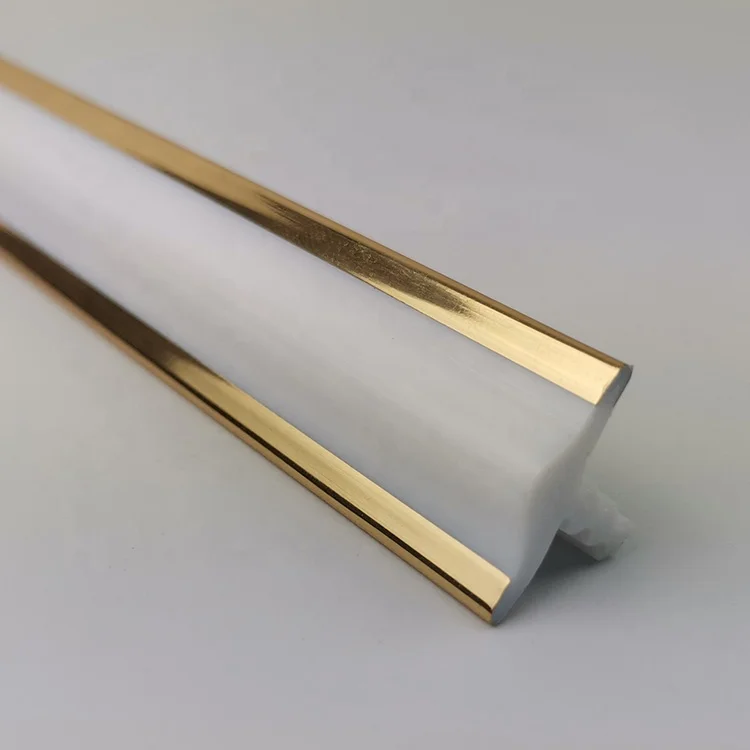

The chrome trim molding strip manufacturers play a crucial role in the automotive industry by combining functionality with aesthetic appeal. With a focus on quality, innovation, and customization, these manufacturers not only enhance the visual aspects of vehicles but also contribute to the overall experience of vehicle ownership. As the automotive landscape continues to evolve, the role of chrome trims will also adapt, reflecting changing consumer preferences and technological advancements. In this competitive market, the commitment to quality and sustainability will be essential for manufacturers looking to thrive in the years to come.

In conclusion, the sealing strip tape factory stands as a testament to human ingenuity and the spirit of innovation. Through the use of advanced technology, sustainable practices, and a commitment to quality, these factories produce essential products that play a significant role in various industries. As the demands of the market continue to evolve, sealing strip tape factories are poised to remain at the forefront of manufacturing, ushering in new advancements that will shape the future of adhesive technology. Investing in these factories means investing in quality, reliability, and a sustainable future.

China's production of EPDM sponge rubber seals has significantly contributed to global industries, combining innovation with quality. With their excellent characteristics like weather resistance, temperature stability, and chemical resistance, EPDM seals offer effective solutions across various applications. As industries continue to evolve and advance, the demand for reliable sealing solutions will persist, making EPDM sponge rubber seals an essential component in ensuring operational efficiency and durability. Manufacturers in China are well-equipped to meet this demand, providing high-quality products that can handle the challenges of modern-day applications.

In conclusion, rubber floor seal strips are a vital component in fostering a clean, safe, and efficient work environment. Their benefits—including dust prevention, energy efficiency, moisture control, enhanced safety, and sound insulation—make them an invaluable asset in various settings. By incorporating these practical solutions, businesses can ensure a higher standard of cleanliness and safety, ultimately leading to improved operational effectiveness and employee satisfaction. Investing in quality rubber floor seal strips is a proactive step towards sustaining a well-maintained workspace.

Manufacturers of thin rubber seal strips typically employ innovative materials and advanced manufacturing techniques. Quality raw materials such as EPDM (ethylene propylene diene monomer), silicone, and neoprene rubber are commonly used to produce seal strips that can withstand various environmental conditions. These materials provide the required flexibility, durability, and resistance to UV radiation, ozone, and temperature fluctuations. Manufacturers must ensure that their products meet stringent quality standards to guarantee performance and longevity.

Seal strips play a fundamental role in preventing water leakage, which is crucial for maintaining the cleanliness and safety of a bathroom environment. Poorly designed or fabricated seal strips can lead to water seepage, causing mold growth, structural damage, and an overall decline in the hygiene of the space. This makes CE certification even more critical for consumers, as it assures them that the seal strips they are buying have been tested and verified for effectiveness.

Despite the growth potential, window seal rubber strip exporters face several challenges. Fluctuating raw material prices, the need for compliance with environmental regulations, and competition from local manufacturers in importing countries all pose potential hurdles. Moreover, economic downturns can lead to reduced construction activities, directly impacting the demand for sealing products.

Sealing strips are materials used to close gaps and seams around doors, windows, and other openings. They are designed to act as a barrier against air infiltration, dust, moisture, and even noise. Typically made from rubber, foam, or silicone, sealing strips come in various sizes, shapes, and thicknesses to cater to specific needs. The primary function of these strips is to create a tight seal that prevents air from escaping or entering, leading to enhanced energy efficiency.

For instance, bold and bright colors might convey energy and excitement, while subdued tones can evoke a sense of sophistication. Additionally, choosing a unique font can enhance brand recognition, making it easier for customers to remember the business. Side light channel letters can blend seamlessly with any architectural style, from modern glass-front stores to rustic establishments, ensuring that they complement their surroundings rather than clash with them.