Silicone foam seal strips are indispensable in modern manufacturing and construction practices. Their combination of flexibility, durability, and temperature resistance makes them a reliable choice for sealing various products across multiple industries. As factories continue to evolve and adapt to new technologies, the demand for high-quality silicone foam seal strips is likely to grow, underscoring the importance of factories that specialize in their production. By understanding the properties and applications of these vital sealing solutions, businesses can make informed decisions that enhance their operational efficiency and product quality.

The global market for weather seals, including V strips, is experiencing significant growth, fueled by several factors. First, increasing consumer awareness regarding energy efficiency and sustainability is driving more homeowners to invest in weatherproofing solutions. Moreover, government regulations aimed at improving energy standards in building codes are encouraging both new constructions and renovations to incorporate these products.

In recent years, the demand for automatic lifting sealing strips has surged, driven by their essential role in packaging and sealing applications across various industries. These innovative seals are designed to enhance product integrity, provide efficient storage solutions, and improve overall operational efficiency. With the global expansion of e-commerce and the rising emphasis on sustainability, exporters of automatic lifting sealing strips are increasingly capitalizing on these trends.

The global market for stainless steel coils has witnessed significant growth, driven by industrial expansion and technological advancements. Emerging economies are experiencing an increase in construction and manufacturing activities, leading to heightened demand for stainless steel products. Furthermore, the rise of renewable energy sectors, such as wind and solar, has created new opportunities for stainless steel manufacturers to supply materials for energy-efficient applications.

Door seal strip prices can vary significantly based on factors such as the make and model of the vehicle, the type of seal strip needed, and whether it's a direct OEM replacement or an aftermarket option. Generally, you can expect prices to range from around $20 to $100 or more. For instance, a standard generic door seal might cost approximately $20, while a specific OEM part for a luxury vehicle could reach upwards of $100. Additionally, it’s a good idea to keep an eye out for seasonal sales or promotions, which can make these necessary purchases even more affordable.

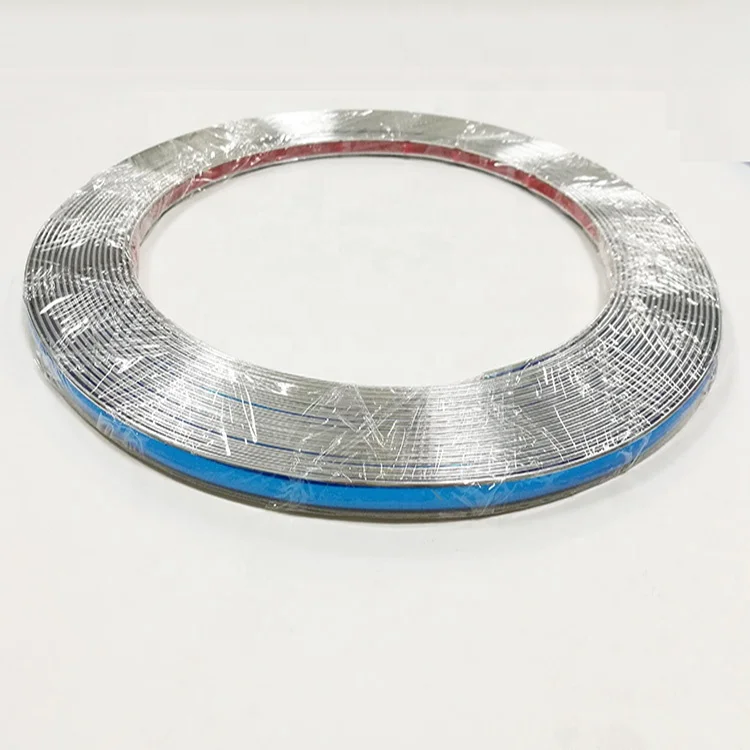

The car trim strip export market is characterized by fierce competition, with numerous players vying for market share. New entrants are continually emerging, providing alternatives that promise innovation and quality. However, established exporters maintain an edge; they often have robust supply chains, established relationships with manufacturers, and a track record of meeting quality standards.

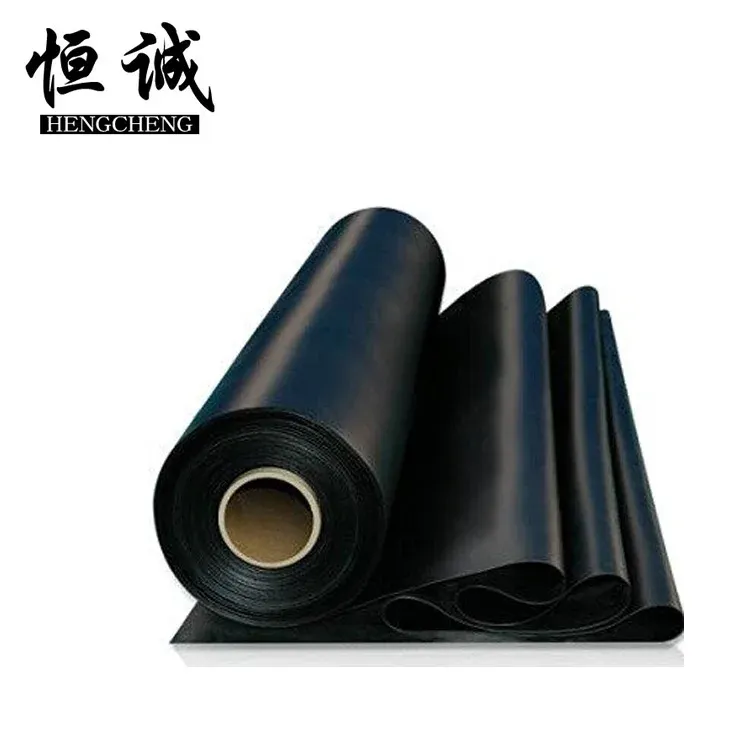

Square rubber seal strips are typically made from materials such as silicone, EPDM (Ethylene Propylene Diene Monomer), or neoprene. These materials are chosen for their durability, flexibility, and resistance to various environmental factors, such as extreme temperatures, moisture, and chemicals. The square shape of these strips allows for a secure fit within grooves or channels, ensuring a tight seal that minimizes leakage and enhances insulation.

In conclusion, CE certification for door and window sealing strips is not just a regulatory checkbox but a commitment to quality, safety, and environmental responsibility. As consumers demand higher standards and energy efficiency, manufacturers must prioritize obtaining this certification. By doing so, they enhance their product offerings, build consumer trust, and contribute to a more sustainable future. The importance of CE certification cannot be overstated; it signifies a product’s ability to perform safely and efficiently in an ever-evolving market, ultimately benefiting both manufacturers and consumers alike.

LED split neon lights are versatile and find applications across various sectors. In commercial spaces, they are widely used for signage, storefront decorations, and artistic displays. The vibrant colors and customizable shapes allow businesses to create eye-catching signage that attracts customers and enhances brand visibility. Furthermore, they are increasingly popular for interior design, used to create ambient lighting in homes, restaurants, and hotels.

In conclusion, high-quality rubber sealing strips are essential components that contribute significantly to the performance, durability, and safety of various applications. Their versatility, longevity, and resistance to harsh environments make them indispensable in a myriad of industries. With the ongoing advancements in materials science and manufacturing techniques, the future of sealing solutions looks promising, paving the way for even more innovative and effective sealing applications. Whether you are in automotive, aerospace, or construction, investing in high-quality rubber sealing strips is an investment in efficiency, safety, and long-term value.