Disinfection is another critical stage in the water treatment process. While physical and chemical methods effectively remove many contaminants, some pathogens may still remain. To eliminate these potentially harmful bacteria, viruses, and protozoa, disinfection methods such as chlorination, ultraviolet (UV) light treatment, or ozone treatment are employed. Chlorination, which has been used for decades, is particularly effective in killing microorganisms. However, the formation of harmful disinfection by-products (DBPs) can be a concern, leading to increased interest in alternative methods such as UV treatment.

In conclusion, modular steel railing systems represent a smart investment for any construction project. Their durability, easy installation, design flexibility, safety features, and cost-effectiveness make them a preferred choice for architects, builders, and property owners alike. Whether used in residential homes, commercial buildings, or public spaces, modular steel railings enhance both functionality and aesthetic appeal, proving to be an excellent addition to any environment. As the demand for sustainable and resilient building materials continues to rise, modular steel railings are poised to remain at the forefront of modern construction practices.

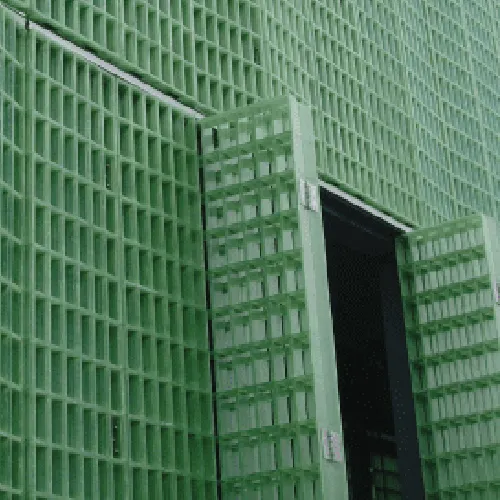

Another notable feature of FRP grating is its versatility in design. Available in various colors, sizes, and thicknesses, it can be tailored to suit the specific needs of different applications. Whether it's for pedestrian walkways, heavy-duty industrial areas, or aesthetic architectural features, FRP grating can be customized to meet the demands of any project.

In various regions, especially in Europe, CHS tubes are often categorized according to national or international standards, which specify the dimensions and mechanical properties. The most widely recognized specifications include those set by the European Committee for Standardization (CEN), the American Society for Testing and Materials (ASTM), and the International Organization for Standardization (ISO). These standards ensure consistency and reliability across different manufacturers and regions.

Safety is a critical concern in industrial settings, and moulded fibreglass grating excels in this area. The grating is manufactured with a slip-resistant surface, which helps reduce the risk of slips and falls—a common hazard in workplaces exposed to water, oil, and other slippery substances. Furthermore, MFG is designed to withstand heavy loads and impacts, making it suitable for use in high-traffic areas while ensuring the safety of workers and equipment.

One of the most significant benefits of using 1354 FRP vessels is their exceptional resistance to corrosion. Unlike metal vessels, which can degrade over time due to chemical reactions with harsh substances, FRP vessels maintain their integrity even when exposed to aggressive environments. This makes them an ideal choice for industries such as chemical processing, wastewater treatment, and offshore oil and gas operations, where conditions can be particularly demanding.

The production process of FRP rods is another significant factor that can influence pricing. Advanced manufacturing techniques, such as pultrusion or filament winding, require specialized equipment and skilled labor. The complexity of the manufacturing process, along with the associated energy consumption, can contribute to higher production costs. Additionally, if a manufacturer invests in improving technology or efficiency, this will likely be reflected in the price of the finished product.

Choosing the right FRP grating supplier can significantly impact the success of your project. By considering factors such as quality, customization, product range, technical support, cost, and sustainability, you can ensure that you partner with a supplier that meets your needs effectively. As the demand for FRP grating continues to rise, having a reliable supplier in your corner will not only enhance the functionality and safety of your installations but also contribute to the long-term success of your projects. Remember, investing time in selecting the right supplier pays off in increased efficiency and satisfaction in the long run.

The growing popularity of FRP water tanks is a testament to their many advantages over traditional storage solutions. Their corrosion resistance, lightweight nature, durability, customization options, and environmental benefits make them an attractive choice for a wide range of applications. As communities continue to face challenges related to water scarcity and quality, incorporating advanced materials like FRP into water tank construction can help address these issues effectively. With their numerous benefits, FRP water tanks are indeed paving the way for a more sustainable future in water storage.