orchid flower support sticks

-

6x6ft fence panels

When it comes to enhancing your outdoor space, one of the most effective solutions is installing 6x6...

-

4x8 chain link gate

The Versatility and Benefits of 4x8 Chain Link Gates When it comes to securing residential, commerci...

-

Creating Inviting Spaces with Stylish Garden Gate Posts for Your Outdoor Sanctuary

The Aesthetic Appeal of Garden Gate Posts When it comes to landscaping and gardening, the details of...

-

50 ft chicken wire

The Versatility of 50% 20 ft Chicken Wire When it comes to versatile materials for outdoor use, chic...

-

60 kyllingetråd

60 Hønse Net En Bæredygtig Løsning til Haven I en verden, hvor bæredygtighed og økologiske løsninge...

-

black metal garden border fence

Black Metal Garden Border Fence A Touch of Elegance and Durability In the world of gardening and lan...

-

Creating Engaging Content for the Modern Digital Landscape and Its Impact on Audiences

The Evolution of 7 t Post A Digital Marketing Phenomenon In the world of digital marketing, innovat...

-

Creating a similar title to 75% x 75% post cap with 15 words

75% x 75% Post Cap A Comprehensive Guide When it comes to investing in the stock market, understand...

-

6-Foot Wide Chain Link Fence Gates for Secure and Stylish Access Solutions

The Perfect Addition A 6-Foot Wide Chain Link Fence Gate When it comes to enhancing security and acc...

-

Affordable Options for Field Fence Pricing and Installation Guide

Understanding the Costs of Field Fence Prices When it comes to securing and enclosing agricultural l...

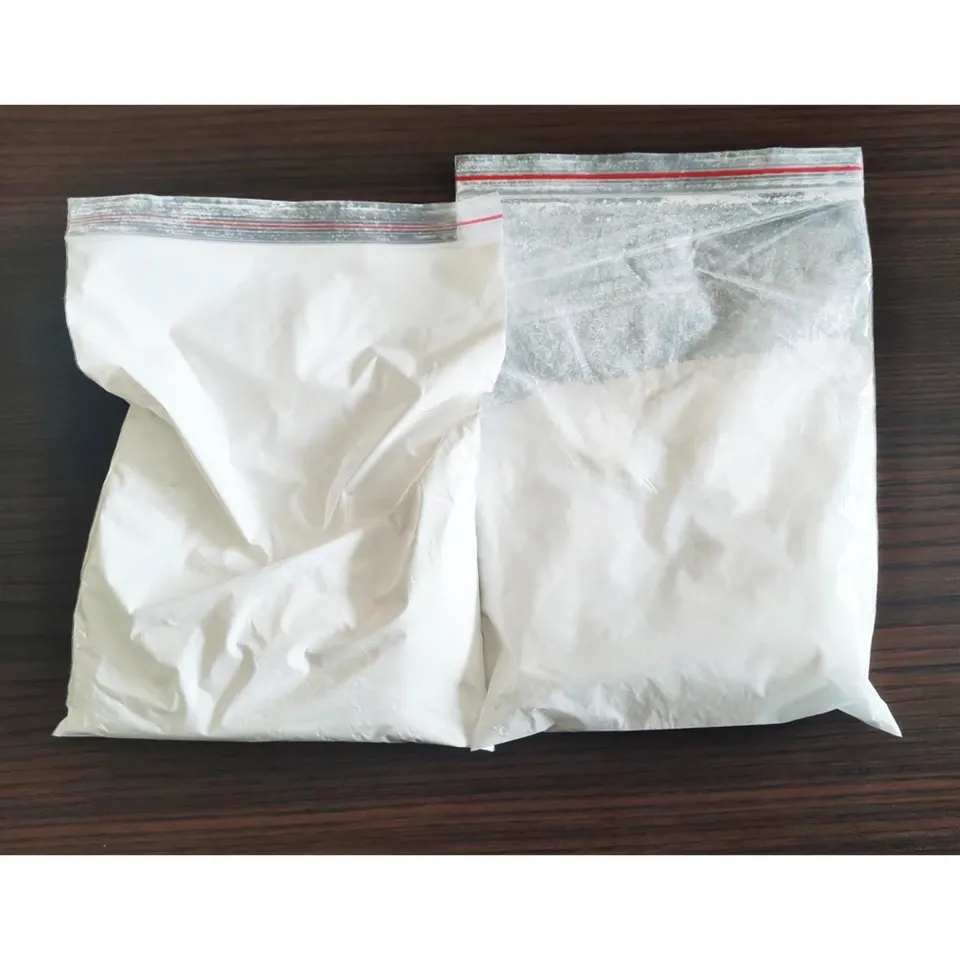

High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product

High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product High-quality barium sulfate is essential for many applications, so it is worth investing in a reputable manufacturer that offers a reliable product