As industries continue to evolve, the demand for effective filtration solutions will only increase. Stainless steel filter vessels, with their combination of durability, efficiency, and adaptability, position themselves as indispensable tools for businesses striving for excellence in fluid management.

Square water storage tanks are characterized by their geometric shape, typically featuring four equal sides. This design allows for optimal use of space, making them ideal for locations with limited ground area. The construction of these tanks can be made from various materials, including reinforced concrete, fiberglass, plastic, and steel. The choice of material often depends on the intended use, environmental conditions, and budget.

1. Corrosion Resistance Traditional steel rebar is prone to rust and deterioration over time, especially in environments with high moisture, chemicals, or de-icing salts. FRP rebar, however, does not corrode, significantly extending the lifespan of structures in aggressive environments, such as coastal areas and industrial sites.

GRP panel water tanks embody a progressive step in water storage technology, blending durability, hygiene, and adaptability. Their capacity to withstand the rigors of the environment and ease of customization make them a prudent choice across various sectors. As the world continues to seek sustainable and efficient solutions, GRP panel water tanks stand out as a testament to innovation meeting necessity, ensuring safe and reliable water storage for years to come.

In conclusion, fiberglass water storage tanks offer a combination of durability, safety, and cost-effectiveness, making them a superior choice for various water storage needs. Their lightweight design allows for easy transportation and installation, while their customizable nature ensures that consumers can find the perfect tank tailored to their requirements. By choosing fiberglass, individuals and businesses alike can enjoy peace of mind knowing that their water is stored safely and effectively. As water demands continue to rise, fiberglass water storage tanks stand out as a reliable solution for the future.

While each step of the GRP Podium is distinct, they are interconnected and should be approached holistically. Strong goals can help foster resilience, as having a clear purpose provides motivation during tough times. Likewise, recognizing progress can reinforce one’s resilience, creating a feedback loop that encourages perseverance. When individuals adopt a comprehensive approach to these steps, they enhance their likelihood of success.

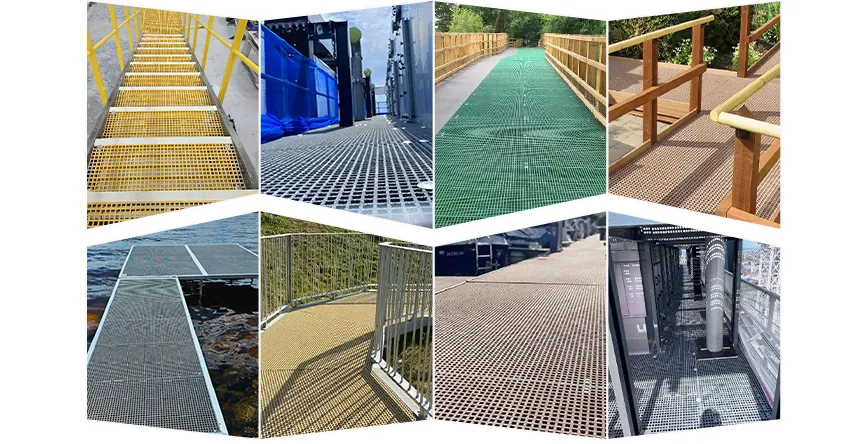

One of the most significant advantages of GRP walkway grating is its exceptional corrosion resistance. Traditional materials like steel are often susceptible to rust and deterioration when exposed to harsh environmental conditions, such as chemicals, moisture, and UV rays. In contrast, GRP grating remains unaffected by these elements, ensuring its longevity even in the most challenging settings. This characteristic makes it a favorite for industries such as wastewater treatment, chemical processing, and marine applications, where exposure to corrosive substances is unavoidable.

Grating floor plates are also highly customizable, making them suitable for a wide range of applications. They can be fabricated in various sizes, shapes, and materials to meet specific project requirements. For example, lightweight aluminum grating is often chosen for applications where portability is essential, while heavy-duty steel grating is preferred in areas that require extra strength and durability. Additionally, fiberglass grating provides excellent corrosion resistance, making it ideal for environments exposed to harsh chemicals or moisture.

3. Accessories and Installation Depending on your needs, you may require additional fittings, such as outlets, inlets, or overflow pipes. Ensure that the tank you select provides these options or that they can be easily added later. Additionally, consider the installation process and whether professional assistance is needed.

Grating floor plates are also highly customizable, making them suitable for a wide range of applications. They can be fabricated in various sizes, shapes, and materials to meet specific project requirements. For example, lightweight aluminum grating is often chosen for applications where portability is essential, while heavy-duty steel grating is preferred in areas that require extra strength and durability. Additionally, fiberglass grating provides excellent corrosion resistance, making it ideal for environments exposed to harsh chemicals or moisture.

A vessel water purifier is typically a standalone unit designed to filter and purify water, making it safe for drinking and cooking. These purifiers use various technologies, such as activated carbon filters, UV sterilization, and reverse osmosis, to eliminate impurities, harmful microorganisms, and contaminants from the water. As a result, they provide an effective means of ensuring that the water we consume is free from harmful substances.

Another compelling reason for the growing popularity of floor grating panels is their versatility. These panels can be customized in various sizes, shapes, and materials to suit specific design needs. For example, fiberglass panels are lightweight and corrosion-resistant, making them ideal for facilities in coastal areas. In contrast, aluminum grating provides strength and durability for heavy-duty applications. The aesthetic aspect should not be overlooked either; floor grating panels can blend seamlessly into a variety of design themes, from industrial chic to contemporary minimalism.

Safety is a critical consideration in industrial settings. Stainless steel grating is designed to provide a slip-resistant surface, minimizing the risk of accidents. Its open grid design allows for the quick drainage of liquids, reducing the likelihood of standing water and potential slip hazards. This characteristic is particularly beneficial in wet environments, such as kitchens or manufacturing plants, where spills are common. Additionally, stainless steel’s inherent strength allows it to support heavy loads without deforming, further enhancing workplace safety.

FRP structural sections find application in a variety of fields, spanning from civil engineering to aerospace. In civil infrastructure, FRP is increasingly used in bridge construction, where its lightweight characteristics minimize the load on supporting structures. Additionally, FRP is used in retrofitting existing structures, providing added strength without significantly increasing weight.